Sidechannel Blowers

Induvac provides a wide range of sidechannel blowers. The range begins at 0.2 kW at ends at 22 kW. All side channel blowers are made of cast aluminum to guarantee the high quality. The blowers are competitively priced and available from stock. Construction features of the VACOM side channel blower are the simplicity of the construction, the very reliable operation and low maintenance.

Reliable design

The standard VACOM® design, with housing and impeller made of aluminium alloy, is a direct drive configuration, with a dynamically balanced impeller, fitted directly on the motor shaft. The impeller rotates inside of the stator housing with a very small clearance. Larger models include housings in cast iron. The absence of lubricants guarantees a 100% oil free vacuum or compression. Construction features of the VACOM® side channel blower are the very reliable operation and low maintenance. VACOM® blowers are directly driven, impellers fixed directly on the drive shaft. Impeller bearing is installed in the front cover and easily to assemble and disassemble. Machines are small and lightweight. VACOM® blowers are already available with differential pressures up to 700 mbar, with maximum capacities of 2000 m3/h.

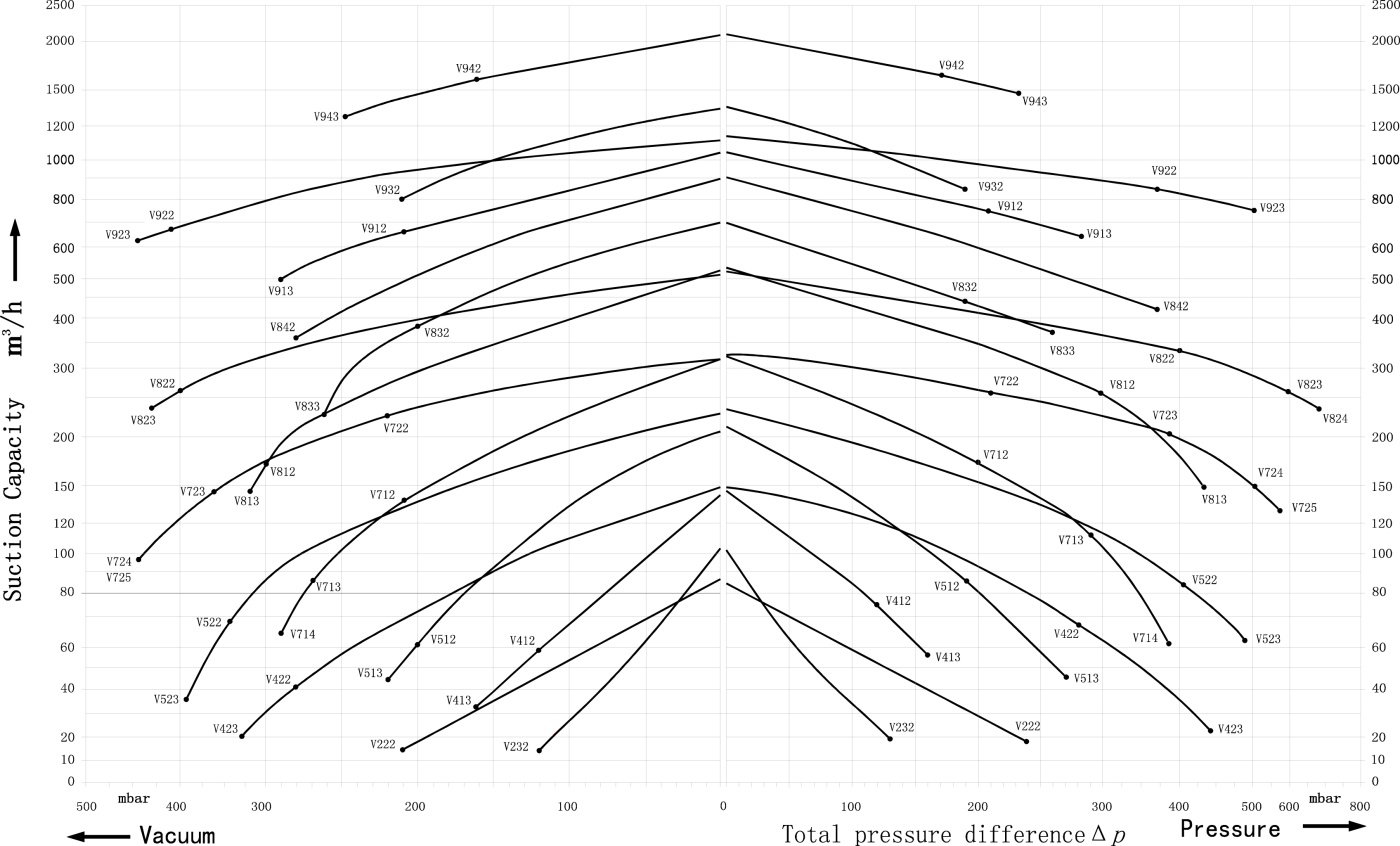

Overview curves

Features Vacom sidechannel blowers

• Suitable for vacuum and compression

• Compact construction

• Pressure differences from 0 to 700 mbar

• Low maintenance

• Stable and vibration free

• Easy to install

• Very low noise level

• Horizontal and vertical use

• Oil-free compression so no contamination of the medium

Downloads side channel blowers

SINGLE STAGE SIDE CHANNEL BLOWERS 3 PHASE

| Type | Power | Capacity | Vacuum | Pressure | ||

| kW | m³/hr | mbar | mbar | |||

| VC 302-010 | 0,2 | 55 | 80 | 90 | ||

| VC 304-230 | 0,4 | 105 | 120 | 130 | ||

| VC 307-410 | 0,75 | 145 | 160 | 150 | ||

| VC 311-510 | 1,1 | 210 | 150 | 150 | ||

| VC 315-510 | 1,5 | 210 | 230 | 220 | ||

| VC 322-510 | 2,2 | 210 | 250 | 310 | ||

| VC 322-710 | 2,2 | 318 | 200 | 190 | ||

| VC 322-730 | 2,2 | 420 | 160 | 150 | ||

| VC 330-710 | 3,0 | 318 | 280 | 280 | ||

| VC 330-730 | 3,0 | 420 | 240 | 230 | ||

| VC 340-710 | 4,0 | 318 | 290 | 350 | ||

| VC 340-730 | 4,0 | 420 | 260 | 290 | ||

| VC 340-810 | 4,0 | 530 | 200 | 180 | ||

| VC 355-810 | 5,5 | 530 | 300 | 300 | ||

| VC 355-830 | 5,5 | 700 | 220 | 220 | ||

| VC 375-810 | 7,5 | 530 | 340 | 420 | ||

| VC 375-830 | 7,5 | 700 | 300 | 320 | ||

| VC 375-910 | 8,5 | 1050 | 200 | 190 | ||

| VC 311-910 | 12,5 | 1050 | 260 | 290 | ||

| VC 311-930 | 12,5 | 1370 | 210 | 200 | ||

| VC 315-943 | 15,0 | 2050 | 190 | 170 | ||

| VC 318-910 | 18,5 | 1050 | 350 | 500 | ||

| VC 318-943 | 18,5 | 2050 | 260 | 240 |

DOUBLE STAGE SIDE CHANNEL BLOWERS 3 PHASE

| Type | Power | Capacity | Vacuum | Pressure | ||

| kW | m³/hr | mbar | mbar | |||

| VC 305-220 | 0,55 | 85 | 200 | 200 | ||

| VC 307-220 | 0,7 | 85 | 210 | 240 | ||

| VC 311-320 | 1,3 | 110 | 280 | 290 | ||

| VC 315-420 | 1,5 | 150 | 320 | 310 | ||

| VC 322-420 | 2,2 | 150 | 320 | 420 | ||

| VC 322-720 | 2,2 | 320 | 220 | 210 | ||

| VC 330-520 | 3,0 | 230 | 380 | 450 | ||

| VC 340-520 | 4,0 | 230 | 390 | 500 | ||

| VC 340-720 | 4,0 | 320 | 400 | 370 | ||

| VC 355-720 | 5,5 | 320 | 420 | 530 | ||

| VC 375-720 | 7,5 | 320 | 420 | 610 | ||

| VC 375-820 | 7,5 | 520 | 380 | 360 | ||

| VC 311-820 | 11,0 | 520 | 460 | 570 | ||

| VC 311-840 | 11,0 | 900 | 280 | 370 | ||

| VC 315-920 | 15,0 | 1110 | 410 | 370 | ||

| VC 318-920 | 18,5 | 1110 | 440 | 490 | ||

| VC 318-940 | 18,5 | 1940 | 240 | 210 |

DOUBLE STAGE SIDE SCHANNEL BLOWERS HIGH PRESSURE

| Type | Power | Capacity | Vacuum | Pressure | |

| kW | m³/uur | mbar | mbar | ||

| VC 305-214 | 0,55 | 47 | 230 | 290 | |

| VC 315-224 | 1,5 | 47 | 370 | 650 | |

| VC 305-314 | 0,55 | 66 | 250 | 250 | |

| VC 308-314 | 0,81 | 66 | 280 | 350 | |

| VC 315-324 | 1,5 | 65 | 440 | 540 | |

| VC 311-414 | 1,1 | 87 | 300 | 380 | |

| VC 315-424 | 1,5 | 87 | 480 | 450 | |

| VC 333-424 | 3,3 | 87 | 500 | 750 | |

| VC 340-524 | 4,0 | 120 | 500 | 820 | |

| VC 315-553 | 15,0 | 480 | 610 | 830 |

SINGLE STAGE SIDE CHANNEL BLOWERS 1 PHASE

| Type | Power | Capacity | Vacuum | Pressure | |

| kW | m³/hr | mbar | mbar | ||

| VC 102-010 | 0,2 | 55 | 70 | 80 | |

| VC 104-230 | 0,37 | 100 | 110 | 110 | |

| VC 108-410 | 0,80 | 145 | 150 | 160 | |

| VC 111-430 | 1,1 | 180 | 170 | 210 | |

| VC 115-510 | 1,5 | 210 | 190 | 200 | |

| VC 122-710 | 2,2 | 318 | 190 | 190 |

DOUBLE STAGE SIDE CHANNEL BLOWERS 1 PHASE

| Type | Power | Capacity | Vacuum | Pressure | ||

| kW | m³/hr | mbar | mbar | |||

| VC 107-220 | 0,7 | 88 | 210 | 240 | ||

| VC 111-320 | 1,1 | 120 | 240 | 280 | ||

| VC 115-420 | 1,5 | 150 | 280 | 290 |

ACCESSOIRIES

Anodized version

For our customers, vacuum pumps, blower and ventilation systems are not a primary concern, but a product for simplifying their production processes. As a specialist, we immerse ourselves in vacuum, compression and fan technology on a daily basis. Of course we let our customers benefit from the knowledge and experience we gain.

Anodizing is an accelerated electrochemical oxidation process that enhances the natural oxide layer of aluminum. This makes the oxide layer considerably thicker than the natural oxide film. This gives the aluminum a strong corrosion resistance and long-term protection. And thanks to the thicker layer, the metal character is preserved. All Induvac side channel blowers can be supplied in an anodized version. These special blowers are more resistant to environmental influences, such as humid or aggressive vapours, sea air, cleaning agents, etc. Please contact us to discuss the options.